Importance of SWMS for High-Risk Construction Work

One of the most crucial instruments for managing safety when carrying out high-risk construction work in Australia is a Safe Work Method Statement (SWMS). The Work Health and Safety Regulations mandate it for certain kinds of high-risk construction work. Creating a thorough yet useful work method statement (SWMS) helps guarantee that dangerous tasks are recognised, suitable risk control measures are chosen, and employees are shielded from situations like falls, electrocution from energised electrical installations, or exposure to a flammable or contaminated environment.

Any Businesses or duty holders, including independent contractors, contractors, builders, and the principal contractor on any major construction project, must comprehend how to create, implement, and evaluate a SWMS. In this blog, we will discuss what a SWMS is, when it's necessary, and how crucial it is to everyone's safety in a high-risk environment.

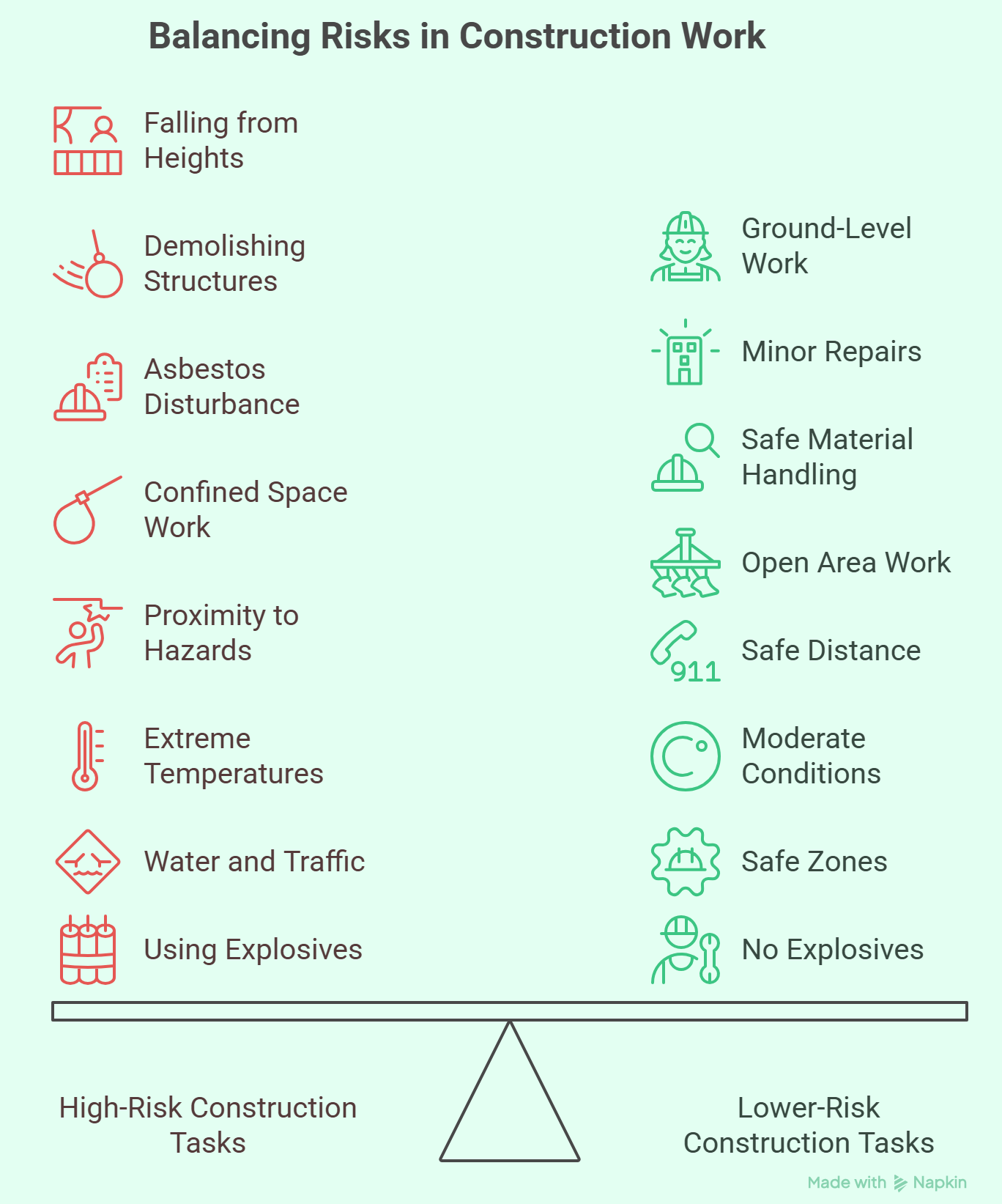

What is defined as high-risk construction work?

Before jumping towards SWMS management, first you need to know about the tasks that are mentioned as high-risk construction work. Due to the risk of dangerous injury that is often linked to these activities, eighteen construction-related tasks are categorised as high-risk.

The 18 construction work actions marked as high risk are ones that:

- Entails the possibility of someone falling more than three metres.

- Is carried out on a telecommunication tower

- Involves demolishing a load-bearing component of a structure or any component connected to the structure's physical integrity.

- Includes, or is probably going to include, asbestos disturbance

- Involves structural repairs or overall alterations that require temporary support to prevent collapse

- It is done in or close to a small area.

- Is done in or close to a tunnel, shaft, or trench that has been excavated deeper than 1.5 metres

- It is done on or close to pipes or pressurised gas distribution mains.

- It is done on or close to fuel, chemical, or refrigerant lines.

- Is done on or close to powered electrical services or installations.

- It is conducted in a location that might have a flammable or contaminated atmosphere.

- Includes precast or tilt-up concrete

- It is conducted in a location with artificial temperature extremes.

- It is done in or close to water or another liquid that poses a drowning risk.

- Entails diving work.

- Is done on, in, or close to a shipping channel, railway, road, or other corridor used by vehicles other than pedestrians

- It is done in an area of a workplace where powered mobile plants are moving.

- Entails using explosives.

What is meant by SWMS?

A useful document that describes how to safely complete high-risk construction work is called a Safe Work Method Statement (SWMS). To put it simply, it describes what must be done, what might go wrong, and how to keep everyone safe. It is intended to ensure that all employees are well aware of the risks related to their jobs and how to mitigate them. It also identifies the person in charge of overseeing the work and maintaining current safety protocols.

Although SWMS has a different function, many people mistake it for other safety documents. A Job Safety Analysis (JSA) divides a task into smaller steps, while a risk assessment examines potential hazards. For high-risk activities, a SWMS goes one step further and unifies everything into a single plan that is mandated by law.

Legal Requirements for SWMS in Australia

SWMS is made mandatory by the Work Health and Safety (WHS) Regulations in Australia. Before beginning high-risk construction work, any company must create a SWMS.

Safe Work Australia states that the person conducting a business or undertaking (PCBU), typically the employer or principal contractor, is in charge of making sure that a SWMS is:

- Prepared for every high-risk task

- Executed and adhered to on the job site

- Examined and updated as needed

- Maintained availability to all employees and inspectors.

Serious fines, legal ramifications, or even site closures may result from noncompliance. To understand the responsibility related to SWMS, have a look at the chart below-

Summary of Responsibilities:

|

Role |

Responsibility |

|

PCBU / Employer |

Prepare, implement, and maintain SWMS |

|

Supervisor / Site Manager |

Ensure workers follow SWMS on site |

|

Workers |

Review, understand, and adhere to SWMS instructions |

|

Safety Officer |

Monitor compliance and report deviations |

The goal of a safe work method statement

A SWMS's primary purpose is to assist managers, employees, and anybody else in the workplace in comprehending the regulations set forth to perform high-risk construction work in a safe and healthful manner.

The SWMS-

- Lays out the tasks in a logical order

- Identifies risks and

- Outlines preventative measures

Both straightforward and intricate tasks can be decomposed into a set of fundamental procedures that enable a thorough examination of every aspect of the task for potential risks and incidents. A SWMS's objective is to:

- Determine the personnel, resources, and abilities needed for the task.

- Evaluate and choose control measures (if necessary).

- Describe the activity that needs to be done.

- Plan the task methodically so that it can be finished successfully and efficiently.

The Role of SWMS in Improving Safety on Construction Sites

A SWMS's primary goal is to stop incidents before they start. Guiding employees through every step of a task makes safety planning a regular practice.

When properly executed, SWMS:

- Promotes communication about possible risks between managers and employees.

- Ensures that everyone is aware of their role in ensuring safety.

- Encourages accountability by having employees sign off to show that they understand.

- Equips teams with well-defined response plans for emergencies.

Take a roofing project, for instance. Employees may believe harnesses are optional in the absence of a SWMS. When one is in place, it reduces confusion and improves safety consistency by clearly outlining fall-prevention systems, anchor points, and rescue procedures.

It is crucial to keep in mind that a SWMS is not a document that should be stored away. Actually, it's a living, practical manual that influences day-to-day activities and strengthens a proactive safety mindset.

Benefits of SWMS that make it an important part of every construction job

Beyond merely fulfilling legal requirements, a well-prepared SWMS adds much more value to a construction site. The advantages benefit both companies and employees, encouraging an environment where productivity and safety go hand in hand.

For Companies

- Legal Protection and WHS Compliance: A SWMS shows that a company has managed risks and identified hazards appropriately. It lowers possible liability in the event of an accident or inspection and provides unambiguous proof of adherence to WHS regulations.

- Decreased Downtime and Expenses: Accidents and delays are less likely to happen when safety protocols are thoroughly documented. Workflows become more efficient, there are fewer interruptions, and insurance and repair expenses are reduced.

- Improved Reputation: Companies that actively follow and enforce SWMS procedures are recognised for their professionalism and reliability. A solid safety record makes it easier to draw in reputable customers, contractors, and qualified workers.

- Operational Efficiency: Before work starts, an efficient SWMS makes sure that every member is aware of the proper procedure. This clarity reduces misunderstandings, enhances teamwork, and keeps projects on budget and on schedule.

For Employees

- Clear Expectations: Employees are aware of the precise duties, risks, and safety precautions to take. They can concentrate on their work with assurance and accuracy thanks to this comprehension.

- Confidence in Safety: When employees perceive that management places a high priority on safety through careful planning, it fosters confidence and assurance. They report risks or make suggestions for improvements because they feel safer and more at ease.

- Empowerment: The team working on the project contributes to the creation of an effective SWMS. Employees feel appreciated and assume more responsibility for ensuring safety when they are involved in identifying risks and controls.

How to prepare safe work method statements in easy steps?

.png)

The SWMS should be developed by those who are most familiar with the HRCW to be carried out, such as impacted employees and their health and safety representatives (HSRs).

A system of work should be in place to guarantee that subcontractors have an SWMS in place if the principal contractor is not an employer.

How to prepare a SWMS:

- At the proposed HRCW location, gather the pertinent staff members, their HSRs, and supervisors.

- Examine the planned projects and

- consider any site-specific elements that might affect them.

- Make sure that all suggested HRCW activities are recognised and that risks and hazards are enumerated.

- Choose the risk control strategies and explain them in relation to each of the listed dangers and hazards.

- Evaluate, examine, and update the SWMS as needed. On-site handwritten revisions are possible.

Last words

There is more to a Safe Work Method Statement (SWMS) than just following the law. On a construction project, it is an essential tool for averting major incidents and safeguarding everyone's health and safety. In order to effectively manage hazards, a well-prepared SWMS includes safety representatives, incorporates practical advice, and takes site-specific factors into account.

If you also want your company to be efficient in SWMS management, trust an expert consulting solution like SSOS and book a free consultation today.