Building Safety Culture: The Role of WHS in Construction

Do you know one industry that offers one of the highest-risk environments?

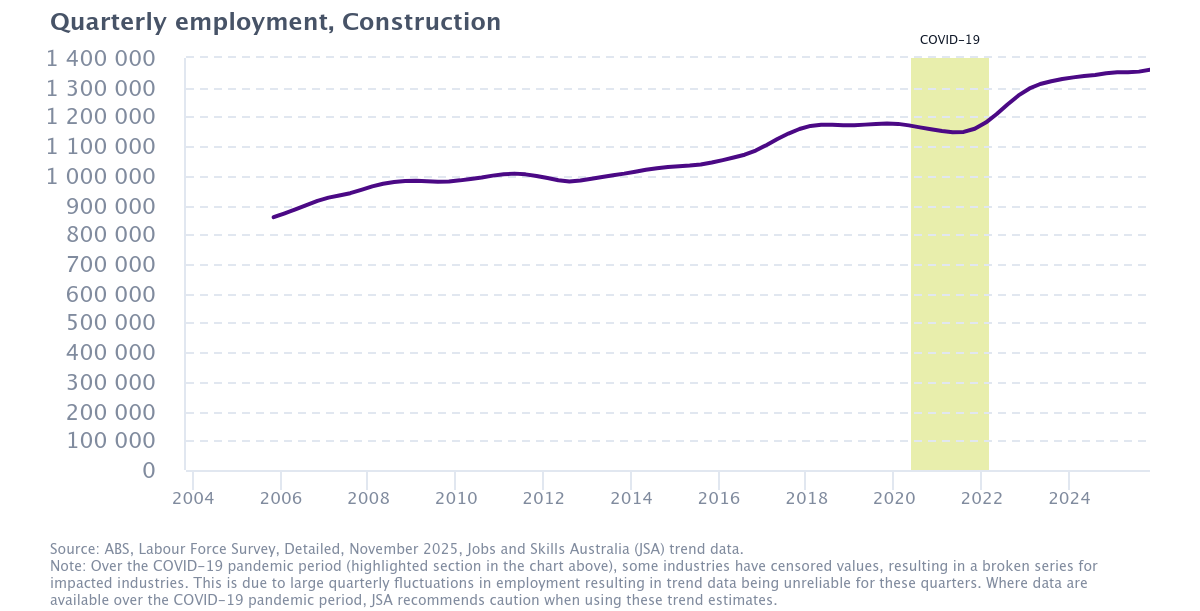

Without any doubt, it will be the construction industry. With over a million workers and $360 billion in revenue annually (roughly 9% of GDP), the construction sector is undoubtedly one of Australia's biggest employers! However, many construction tasks are extremely risky. Therefore, there are numerous safety risks for construction workers, and unfortunately, one construction-related death occurs in Australia every week.

Source: Jobs and Skills Australia

That's why construction site safety is more than a set of guidelines or a checklist. In an industry where employees work with heights, heavy machinery, and unpredictable conditions daily, safety must be more than compliance. WHS (Work Health and Safety) is essential in this situation. It provides construction companies with the framework they need to recognise hazards, prevent accidents, and foster an environment where everyone takes personal responsibility for their own and others' safety.

It takes time to establish this kind of safety culture. It calls for leadership that sets an example, appropriate training, and constant communication. This blog will guide you to understand the concept of safety culture, discuss how WHS promotes safer construction methods and the importance of building a positive safety culture for the industry's future.

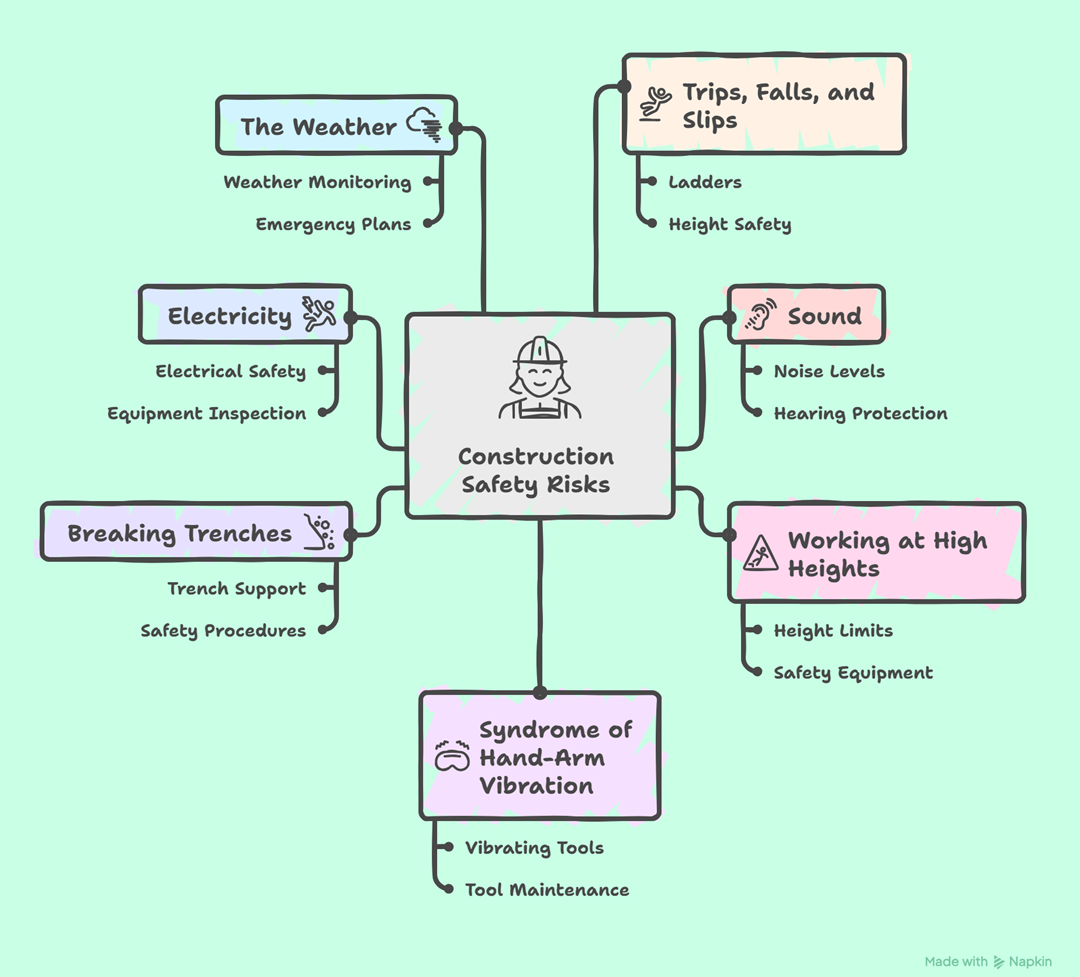

What are the possible risks associated with construction?

As we mentioned earlier, construction is recognised to be one of the most dangerous industries, and you might be wondering how. Well, here are a few common instances-

1. Trips, Falls, and Slips

Ladders are mostly linked to falls, slips, and trips, which are closely related to working at heights. Ladder safety is essential in preventing such incidents.

2. Sound

It may come as a surprise that noise poses a risk to construction safety, but according to UK statistics, excessive noise at work causes hearing impairments in an estimated 12,000 people each year.

3. Working at High Heights

Construction work performed at a height of two metres or more is referred to as working at heights. It is among the leading causes of preventable workplace fatalities and injuries worldwide.

4. Syndrome of Hand-Arm Vibration

Hand-arm vibration syndrome (HAVS) is a chronic disorder that affects the hand's blood vessels and nerves. The main cause of HAVS in construction workers is extended use of vibrating tools and equipment, such as grinders, hammer drills, and concrete breakers.

5. Breaking Trenches

All workers engaged in trenching work face significant safety risks, but the biggest risk is posed by collapsing trenches or cave-ins, which are more likely to cause worker fatalities than other excavation-related incidents.

6. Electricity

It has long been known that electrical exposure poses a risk to construction safety, with electrocutions being the most fatal. In order to guard against electrocutions and other hazardous electrical exposures.

7. The Weather

Workers on construction sites are more prone to encountering severe weather because they are outdoors. Unexpected weather changes can affect worker alertness and performance by causing cold stress, heat stress, and heat stroke.

What is intended by a safety culture in the construction industry?

Any construction project must have a safety culture, which extends beyond merely following the law. It's a way of thinking, a set of principles, and a dedication to each employee's welfare on the job. Fundamentally, a safety culture is a set of values that all members of a construction company or project share and that prioritise the safety of all workers and stakeholders.

A construction project's success depends a lot on its safety culture. It's a dedication to encouraging an atmosphere in which mishaps and injuries are not tolerated as "part of the job." It aims for zero incidents instead. In the construction industry, it is mandatory to establish an effective safety culture.

What are the 4 C's of safety culture?

.png)

Engaging and committing your employees is essential to the success of your health and safety policy. This is often referred to as a "positive culture of health and safety."

The following are the four "Cs" of a positive safety and health culture:

- Competence: It involves hiring, educating, and providing guidance.

- Control: It focuses on assigning tasks, obtaining dedication, training, and oversight.

- Cooperation: It should be maintained between people and organisations.

- Communication: Can be done through written, spoken, and visual means.

How many key components are there for safety culture in construction?

.png)

The following are essential elements of a construction safety culture:

- Identification and reporting of hazards: Employees are urged to recognise and report possible risks without worrying about reprisals. Timely intervention to prevent accidents is made possible by prompt reporting.

- Accountability: From the site manager to the newest worker, everyone bears responsibility for safety in a safety culture. Accountability is upheld, and roles and responsibilities are clearly defined for safety.

- Leadership and dedication: At the top, there is a strong safety culture. Leaders need to set a good example by genuinely caring about safety. Employees are more inclined to prioritise safety when they perceive that management values it.

- Constant improvement: A culture of safety is dynamic and ever-changing. Safety processes and procedures are improved through frequent reviews, assessments, and lessons learned from incidents.

- Training and communication: It's critical to communicate safety policies, procedures, and expectations clearly. Frequent safety training guarantees that all employees understand possible risks and how to reduce them.

- Participation and empowerment: Employees are urged to actively take part in safety campaigns, offer suggestions for enhancements, and offer feedback. Their participation encourages a feeling of pride in the safety procedure.

The importance of creating an effective safety culture

Construction companies have historically implemented a number of safety risk mitigation strategies, such as fall protection systems, training, regulations, and ensuring that workers have the tools they need for their jobs.

A basic safety programme by itself is unlikely to meet an organisation's risk management goals, so while these are a good starting point, a safety culture that encompasses the health and well-being of the workforce is essential. Instead, company executives ought to work to instil a safety, health, and wellness culture across the board.

A positive culture encourages good decision-making and communication. It could promote ongoing training, attentiveness on the job site, and the right response to a problem. By involving workers in the development of a positive safety and well-being culture, awareness is raised, and initiatives to prevent physical harm and promote mental health can become routine rather than an afterthought.

What is WHS in construction?

Workplace safety and health (WHS) refers to the regulations and procedures that help keep people safe. WHS is also referred to as occupational health and safety (OHS). Protecting employees' physical and mental well-being and safety from risks and hazards at work is required by law. This covers your employees as well as other individuals, like clients or guests. Businesses can hire OHS consulting services to stay updated and compliant.

WHS regulations in Australiarequire your company to have a safe workplace. This holds true for enterprises of all sizes, including partnerships, sole proprietorships, and corporations.

By handling your WHS responsibilities, you can:

- Improve employee productivity

- Retain employees

- Lower workers' compensation and injury costs

How is WHS in construction related to establishing a safety culture?

Teams are protected, and incidents are greatly decreased when WHS standards are followed. Promoting a proactive safety culture requires compliance training. Among the main advantages that make WHS relatable are:

- Proactive risk mitigation: Giving employees the tools they need to recognise and manage potential hazards before they happen.

- Situational risk awareness: Teaching staff members about risks unique to their jobs and risk-reduction techniques.

- Increased morale and output: A safer setting encourages concentration and trust, which enhances team performance as a whole.

What are the WHS obligations businesses must follow?

There are primarily two obligations that your company must meet:

- Make sure your employees are safe and healthy.

- Not endanger the well-being and security of others.

However, to meet the obligations properly and to stick to the laws, you must fulfil some requirements-

- Maintain a secure workplace.

- Maintain safe working practices by following the policies and procedures you have put in place to reduce risks and hazards.

- Provide secure equipment and buildings that you keep up.

- Make sure that equipment, structures, and materials are used, handled, and stored safely.

- Put safeguards in place to reduce or eliminate the risk of psychosocial hazards.

- Provide employees with access to sufficient facilities that you keep up to date.

- Provide any safety-related information, instruction, training, or supervision that is required.

- Keep an eye on employee health and working conditions.

What are the common WHS challenges in construction?

Expert WHS consultants in Sydneyand all-around Australia express that it's not always simple to maintain high safety standards on a construction site. Strong WHS practices must be implemented and maintained continuously due to the particular challenges presented by the nature of the work.

1. Unpredictable site conditions and high-risk activities

Operating large machinery, working at heights, and dealing with erratic conditions like bad weather or unstable ground are all common tasks in construction.

2. Production demands and time constraints

Tight project deadlines may cause teams to neglect safety precautions or rush tasks. On busy construction sites, striking a balance between safety and productivity is still one of the most difficult tasks.

3. Inconsistent compliance by subcontractors

There may be misunderstandings and gaps in WHS compliance as a result of different crews and subcontractors adhering to different safety standards. Maintaining everyone's alignment requires regular supervision and communication.

4. Keeping safety and cost investments in balance

Companies may be tempted to reduce their safety expenditures due to financial constraints. However, by decreasing incidents and increasing efficiency, investing in appropriate WHS measures ultimately results in cost savings.

How to practice safety culture by adhering to WHS?

As new risks arise, regulations change, and technology advances, so too must effective safety training. Frequent WHS training guarantees that employees stay knowledgeable and ready. Training should definitely include:

- Risk management: Giving teams the tools they need to identify and reduce changing workplace risks.

- Correct use of protective gear: Making sure employees understand how to use safety gear properly.

- Emergency response skills: Teaching evacuation procedures and first aid to minimise damage during incidents is an example of emergency response skills.

- Regular evaluations of safety: Safety is always at the forefront, thanks to toolbox talks and audits.

- Identification of safe conduct: Teams are encouraged to follow WHS regulations by offering incentives for compliance.

Innovative WHS practices for an evolving sector

In order to handle the complexity of contemporary construction, advanced safety procedures are essential. These consist of:

- Wearable technology: By continuously monitoring the conditions of employees, gadgets such as sensor-equipped helmets improve safety.

- Remote monitoring and drones: These technologies increase worker safety during site inspections by reducing the need for workers to enter dangerous areas.

- Data-driven insights: By examining incident reports, organisations can spot patterns and anticipate dangers.

Conclusion

It takes dedication, open communication, and sincere concern for the people on the job site to create a strong safety culture. Teams function more effectively, risks are reduced, and projects go more smoothly when WHS is integrated into everyday operations rather than being a formality. Ultimately, having a safe website reflects a company's professionalism and values in addition to being required by law. Ensuring safety means trusted business, and it starts with everyone taking responsibility.