SWMS in Australia: 7 Must-Have Elements for Every Safe Work Method Statement

Under the Work Health and Safety Regulation of 2017, any work that is categorised as "high-risk construction work" must have a Safe Work Method Statement (SWMS). It ensures that everyone on the site, from employees to managers, is aware of the risks, hazards, and control mechanisms related to certain tasks.

Consider it a useful manual that aids in preventing mishaps and injuries by outlining risk management procedures in detail before work starts. Well, SWMS is not a single document; it has numerous essentials that make it complete. Do you know what a safe work method statement must include? We have got your back.

If you are planning for your business to be successful in the SWMS management in the right way, this guide is for you. We will discuss the basics of SWMS and its seven essentials to help your business in Australia to stay compliant.

What type of work legally requires SWMs?

A SWMS is mandated by the WHS Regulations for eighteen types of high-risk construction projects. Any high-risk construction project must have a Safe Work Method Statement (SWMS), which covers tasks that-

- Include the chances of someone falling more than two meters.

- They are conducted on a telecom tower.

- Involve demolishing a structure's load-bearing component.

- Involve tearing down a component of a building that compromises its structural stability.

- Entail disturbing asbestos, or are likely to include

- Involve structural repairs or modifications that call for short-term support to keep the structure from collapsing.

- Are conducted in or close to a tunnel, a shaft, or a trench that is deeper than 1.5 meters.

- Incorporate the use of explosives.

- Are done on or close to pipes or pressurised gas mains; are done on or close to fuel, chemical, or refrigerant lines

- Are performed on or close to electrical services or installations that are powered.

- Are conducted in a location that can have a flammable or polluted atmosphere.

- Use precast or tilt-up concrete.

- Are conducted on, within, or close to a road, railroad, shipping lane, or other traffic corridor that is used by vehicles other than pedestrians.

- Are conducted in a section of a workplace where powered mobility equipment is in motion.

- Are conducted in regions with artificial temperature extremes.

- Entail diving work and are done in or close to water or other liquids where there is a risk of drowning.

Who should prepare a SWMS?

The best person to develop the SWMS alongside the workers directly involved in the task is the person in charge of high-risk construction work. This typically means that a SWMS is created by the subcontractor for both themselves and their employees, or by the builder for their employees.

To decide who is best suited to draft the SWMS, the principal contractor, builder, and subcontractors must speak with one another.

When creating a SWMS, managers, contractors, leaders, and employees should all be involved. It is crucial to consult employees so they are aware of the SWMS's specifics and what they must do to put risk controls in place and keep them up to date. While creating a SWMS, the workplace's Health and Safety Representative should be contacted as well.

What seven components should be included in a SWMS?

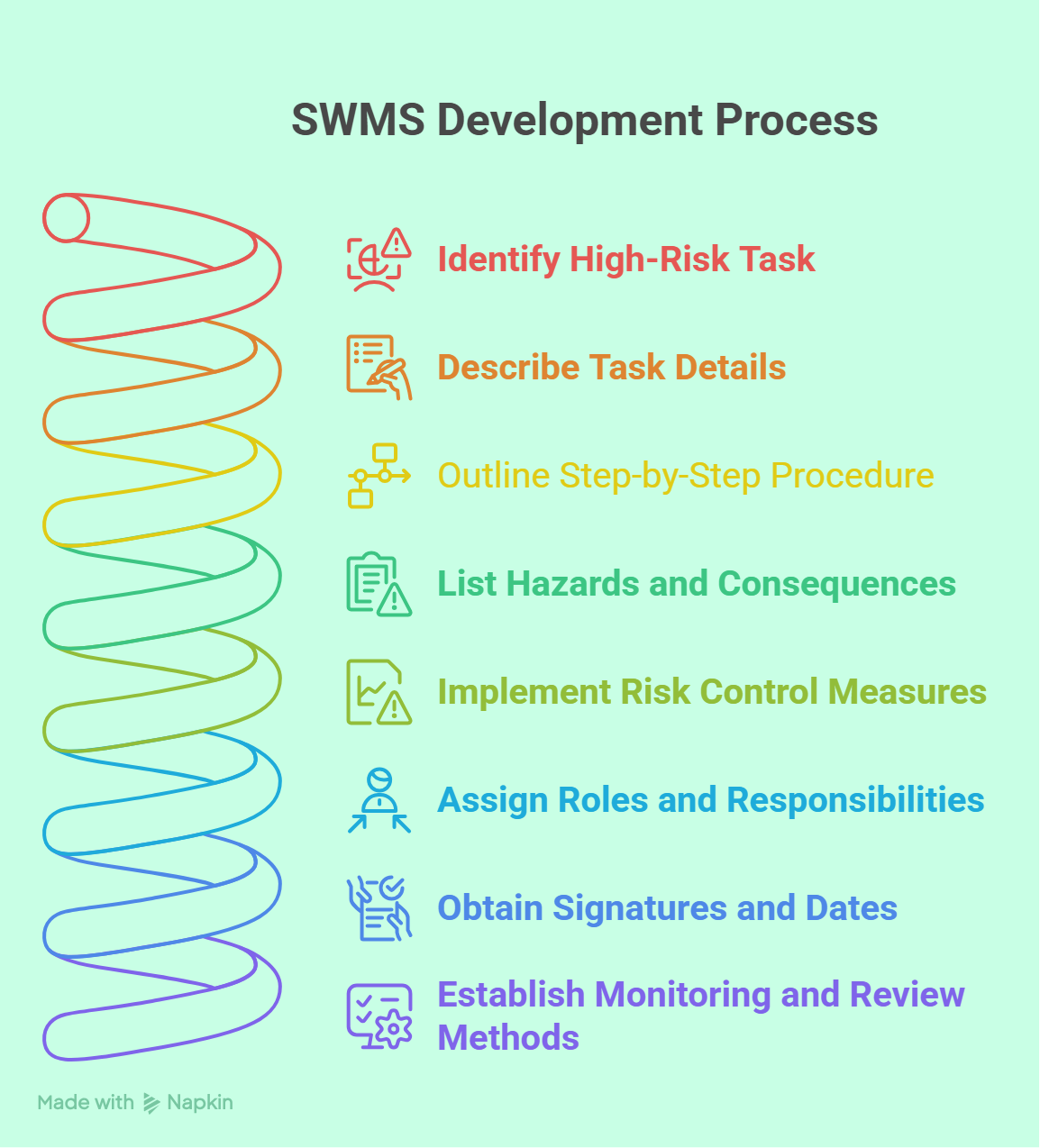

In Australia, SWMS that are both compliant and efficient must include comprehensive, task-specific data. The essential seven elements that a Safe Work Method Statement should include are listed below:

1. Step-by-Step Procedure

Divide the work into clear, sequential steps that employees may follow. This aids in locating potential dangers and the areas that require the application of control measures. Every step should be sufficiently transparent for any competent worker to comprehend and follow.

2. Description of the High-Risk Task

Describe the particular high-risk job activity in detail at the beginning of your SWMS. This should include the task's name, the location where it will take place, and the reasons why Australian WHS regulations classify it as high-risk. For instance, "installing roof sheeting at a height exceeding two meters."

3. Risk Control Measures

Keep a record of the precise risk control strategies you'll use to lessen or completely eradicate each threat. Elimination, substitution, engineering, administration, and PPE should be prioritised in accordance with the hierarchy of control.

4. Hazards and Potential Consequences

Make a list of the potential risks associated with each task stage. Risks, including falls, injuries from physical labour, electric shock, or exposure to dangerous materials, may fall under this category. Incorporate the possible outcomes as well, such as "serious injury or fatality," to assist in conveying the degree of risk.

5. Roles and Responsibilities

Specify who is in charge of each task and safety precautions. This covers workers, subcontractors, site supervisors, and any safety officers.

For instance:

- Site Supervisor: Verify the installation of fall prevention

- Employees: Observe the lockout/tagout protocols.

- Safety Representative: Perform daily sign-offs and inspections.

6. Date and Signatures

Before work starts, the responsible parties must sign and date the SWMS. In order to verify that they are aware of the risks and necessary controls, each employee engaged in the high-risk task should also read, comprehend, and sign the SWMS. As long as they are available on-site and can be audited if necessary, digital signatures are acceptable.

7. Monitoring and Review Methods

Finally, describe how the SWMS will be observed while the work is being done and evaluated if circumstances change. This comprises:

- Digital tracking or sign-off sheets

- Frequent site examinations

- Protocols for halting work if risks increase

- Inspect triggers (e.g., new employees, procedure changes, weather)

How is a SWMS implemented on-site?

Once a SWMS has been created, it must be easily accessible to all employees, supervisors, and other responsible holders engaged in the high-risk construction task. In order to ensure that everyone is aware of the risk management measures, the appropriate personal protective equipment (PPE) to wear, and the protocols to follow in the event that new risks develop, the SWMS should be covered in a pre-start meeting or toolbox talk prior to the start of work.

Work must cease right away if new risks appear or if the SWMS is not being followed. After that, the SWMS must undergo a review procedure to ascertain whether any modifications are necessary.

Is it possible to use a single SWMS for several tasks?

Yes, if several high-risk construction tasks are included in the same job, they can all be covered by a single Safe Work Method Statement (SWMS). Using a powered mobile plant, operating in a small area, and performing a structural modification are a few examples of tasks.

However, the SWMS templete needs to be reviewed and, if needed, updated if the nature of the activity or the site conditions change considerably. The goal is to make sure the SWMS doesn't become unduly detailed with unrelated information that could lessen its efficacy and only incorporates risks and controls pertinent to the particular activity.

Why should a SWMS be reviewed regularly?

In order to maintain its efficacy in risk management, a Safe Work Method Statement is a dynamic document that needs to be evaluated on a regular basis. A review procedure should be triggered by any changes to the workplace, the risks associated with the task, or the individuals performing the work. New equipment, revised risk assessment results, or modifications to personal protective equipment (PPE) regulations are examples of this.

What are common SWMS mistakes to avoid?

- Misidentifying risks as a result of failing to fully evaluate all on-site concerns.

- Failing to update the SWMS on a regular basis as standards, tasks, or situations change.

- Ignoring the necessity of providing workers with adequate SWMS subject training.

- Excluding all pertinent employees, including temporary workers and subcontractors.

- Adding too much depth and technical terms to the SWMS.

- Failing to include employees in the SWMS's development.

- Disregarding the SWMS's legal and compliance obligations.

- Avoiding a formal review and approval procedure.

- Failing to keep an eye on and enforce compliance at the workplace.

- Not recording events and modifications that have an impact on the SWMS.

Where should you keep a SWMS?

Until the related work is finished, the SWMS should be maintained and made accessible at the location where the high-risk construction work will be done, and only the SWMS management will be successful. If it is easily accessible to employees, it can also be maintained electronically.

Conclusion

A Safe Work Method Statement is more than just an additional paper to complete before work starts. When done correctly, it becomes a useful manual that helps everyone understand the risks, the safety culture, and their roles. By incorporating these seven essential components, you can make sure that your SWMS is understandable, fully compliant, and actually helpful rather than something that is put away and forgotten.